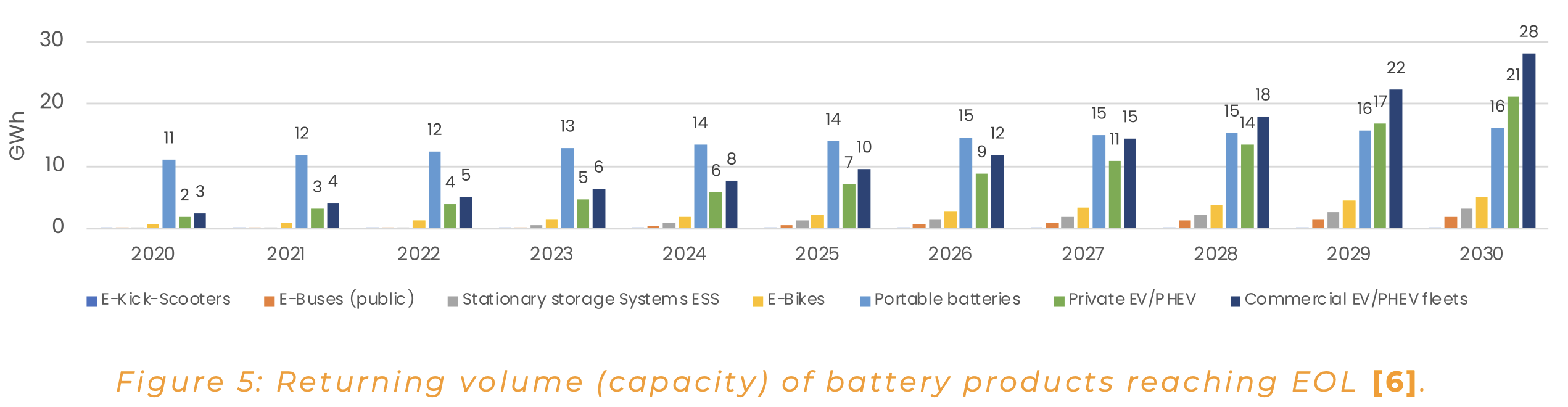

The projected rise in EoL battery volumes is a direct consequence of the rapid expansion of the electric vehicle market. As the EU pushes forward with its ambitious goals for electric mobility and sustainable energy, the number of batteries entering the waste stream is set to escalate, demanding robust infrastructure and innovative solutions to mitigate environmental impact and resource scarcity.

Recycling Infrastructure and Capacity

The report highlights a pressing need to scale up the number and capacity of recycling facilities across Europe. Current recycling processes are inadequate to handle the expected surge in battery waste, necessitating investments in advanced technologies and the expansion of existing facilities. The goal is to reduce waste, promote the integration of secondary raw materials into the European supply chain, and minimise safety risks throughout the battery value chain.

Standardisation and Data Management

A significant challenge identified is the lack of uniform battery standards and insufficient data on battery form, assembly modes, and state of health. These gaps hinder efficient recycling processes and the effective integration of recycled materials back into the production cycle. The EU battery passport regulation aims to address these issues by facilitating better communication and data exchange among stakeholders, ultimately enhancing decision-making for reuse, remanufacturing, and recycling based on comprehensive usage patterns and chemical composition data.

Strategic Research and Innovation Priorities

To address these challenges, the report outlines several strategic research and innovation priorities. Key among these is the development of recycling processes tailored to emerging chemistries, such as sodium-ion and vanadium redox flow batteries. Research activities are directed towards improving the adaptability and flexibility of current recycling processes to accommodate constantly evolving battery compositions and formulations.

Additionally, advancing Life Cycle Assessment (LCA) for next-generation batteries and stationary storage applications is crucial. The European battery passport initiative is also expected to play a pivotal role in enabling better tracking and management of battery data, ensuring a more circular approach to battery life cycles.

Workforce Education and Training

The report also emphasises the importance of educating a competitive workforce qualified to operate within the future European battery value chain. As the industry evolves, there is a growing need for skilled professionals who can drive innovation and maintain the EU’s competitive edge in battery technology and recycling practices.

Conclusion

As the EU navigates the complexities of managing the forthcoming surge in end-of-life batteries, strategic investments in recycling infrastructure, standardisation efforts, and workforce education will be paramount. By fostering a circular economy and enhancing recycling capabilities, Europe can not only mitigate environmental impacts but also secure a sustainable supply of critical materials essential for its green transition.

Source: Bax & Company