China currently dominates the global market, accounting for around 51 percent of cell component manufacturing for Li-ion batteries (LiB).

The Li-ion battery supply chain encompasses four stages: raw material extraction, production (including cell and battery manufacturing and vehicle assembly), consumption, and recycling. This chain begins with mining essential resources like lithium, nickel, cobalt, copper, and graphite, which are then used in cell manufacturing. Components such as cathodes, anodes, electrolytes, and separators are assembled to create cells and batteries.

At the end of their life cycle in EVs, batteries retain 70-80 percent of their initial energy and are often repurposed for grid-connected and behind-the-meter (BTM) applications. Recycling these batteries can recover approximately 95 percent of the metals for use in new battery manufacturing, reducing the need for primary resource extraction and minimizing environmental impacts.

The recycling industry alone is projected to generate a profit pool of around $6 billion by 2040, with total revenue exceeding $40 billion, a significant increase from 2030 values.

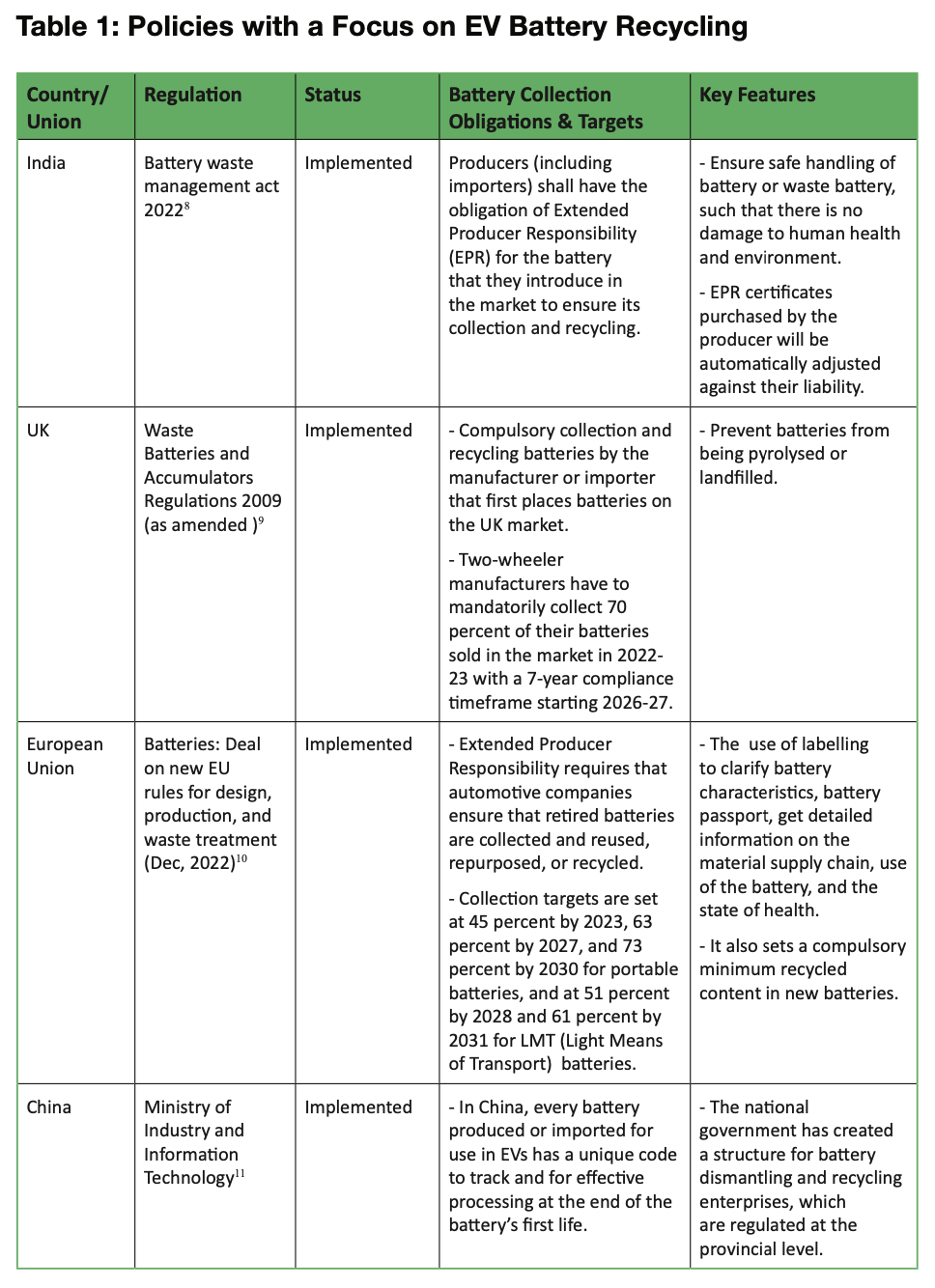

Currently, battery recycling policies are in place in a limited number of countries, including China, the European Union, South Korea, and India. These policies establish battery collection targets, material recovery objectives, and minimum recycled content requirements for new batteries.

In conclusion, the recycling and reuse of EV batteries present a critical global challenge and opportunity. As the EV market grows, addressing resource availability, environmental concerns, and supply chain irregularities becomes paramount. Policymakers worldwide are beginning to recognize the need for comprehensive recycling policies to ensure a sustainable and resilient value chain for EV batteries.

Source: Building a Resilient EV Battery Value Chain | T20